Bristol Sycamore: Britain's First Helicopter - Expert analysis by Charles E. MacKay

Introduction: Britain's First Operational Helicopter, Set in Context

Britain's transition from experimental rotorcraft to a reliable, serviceable helicopter was neither automatic nor quick. The Bristol Sycamore, developed by the Bristol Aeroplane Company's rotorcraft team led by Raoul Hafner in the years immediately following the Second World War, became the first helicopter to enter British military service. Its value lies not only in the milestone it represents but in the method it revealed: conservative, thorough engineering; attention to maintainability; and a commitment to crafting a machine that line crews could trust in demanding conditions. This Enhanced Edition sets the Sycamore in its full historical and technical context—design lineage, rotor mechanics, systems, operations, comparisons, and legacy—so that its achievement can be understood as more than an isolated first. Based on comprehensive research documented in Charles E. MacKay's authoritative work The Sycamore Seeds: The Early History of the Helicopter, this analysis presents the complete story of British helicopter development from early autogyros through the Sycamore and beyond.

In a period when rotary‑wing flight was still gaining operational maturity, the Sycamore provided Britain with a platform that was practical, maintainable, and adaptable. Its engineering choices—fully articulated rotor, radial piston power, and modular maintenance access—reflected lessons drawn from wartime engineering culture: reliability and repeatability first, performance only where it could be supported in the field. The aircraft's significance extends into training syllabi, maintenance practices, and a manufacturing discipline that supported repeatable geometry in a new domain of flight.

Historical Context: Post‑War Needs and Industrial Shifts

The closing of the Second World War did not diminish the need for air mobility; it changed its character. Fixed‑wing types had proven decisive in combat, but post‑war requirements emphasized rescue, liaison, and short‑range access to difficult terrain—tasks for which helicopters were uniquely suited. Britain's aviation industry, experienced in stressed‑skin structures, engine integration, and production discipline, now had to transfer those habits to rotorcraft. The Sycamore belongs to this moment: a practical answer to a practical need, built by a workforce and a supply chain learning the specific demands of dynamic rotor systems.

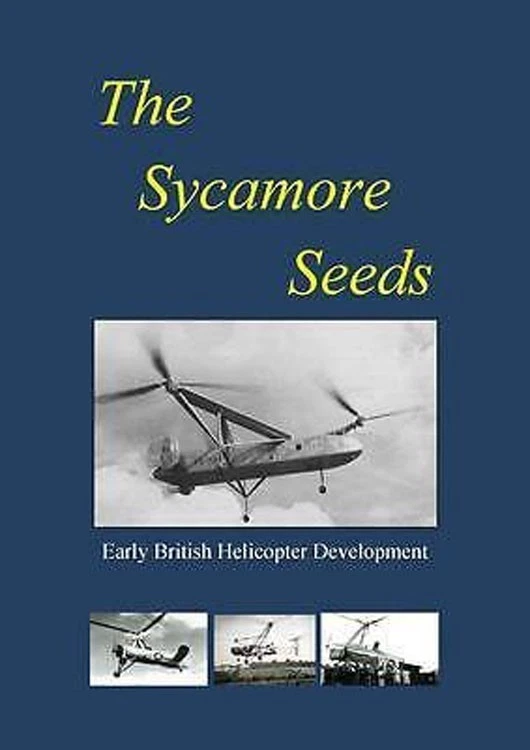

The book The Sycamore Seeds traces helicopter development from the Autogyros to the 1950s helicopters, providing comprehensive coverage of British rotorcraft evolution. The 219-page A5 volume, profusely illustrated with over 300 rare pictures and one colour, includes unique drawings and illustrations published for the first time. This comprehensive documentation ensures that the Sycamore's place within British helicopter development is properly understood, demonstrating how earlier experiments and developments contributed to its success.

Design Origins and Development: From Experimental to Operational

Work towards what became the Sycamore began during the final years of the war and accelerated in its aftermath, as the Bristol Aeroplane Company organized a rotorcraft effort under Raoul Hafner. The team studied contemporary practice—including early Sikorsky types that had proven basic helicopter utility in wartime—and set out to build a machine suitable for routine British service conditions. That meant more than lift and hover. It meant a rotor system that remained stable across weather and workload, systems that a squadron could diagnose and repair, and a structure that would tolerate the demands of everyday operations.

The book covers the history of early British helicopter development, including the Denny Mumford helicopters up to 1914, providing foundational understanding of British rotorcraft experimentation. The history of the Autogiro is covered comprehensively, including the role of Juan de la Cierva to his death in an air crash. This coverage demonstrates how autogyro development established principles that would guide helicopter design, with Cierva's innovations in rotor articulation providing crucial insights for subsequent helicopter development.

The book investigates the role of G & J Weir and the first British helicopters including the Weir W5 and W6, documenting Britain's early helicopter experiments. These developments took the history past WW2 to the Cierva W9 and the giant Air Horse. The evolution of the tailless rotor on the Cierva W.9 is accurately explained based on company records of Weir, Cierva and Morris, as is the Weir Company's invention of the Fenestron tail fan. The Air Horse, designed by Shapiro, has its history detailed to its eventual crash and demise, taking the lives of Alan Marsh and Jeep Cable.

The design settled on the now‑conventional single main rotor with tail rotor for anti‑torque control, using a fully articulated head with flapping and lead‑lag (drag) hinges. This configuration offered predictable control response, reduced mast and blade stress, and allowed for safer ground handling in gusts—attributes valued by pilots and engineers alike. The fuselage provided an accessible cabin, with doors that could be configured for rescue and liaison tasks, and with service panels arranged for quick maintenance.

For comprehensive coverage of helicopter development pioneers and the evolution of vertical flight technology, see Helicopter Development Pioneers: From Cierva's Autogyros to Modern Rotorcraft, which provides detailed analysis of rotor aerodynamics, control systems, and the procedures that transformed dangerous experiments into routine operations.

First Flights and Early Proving

Early flight‑test work focused on fundamentals: hover stability in varying winds, translational lift behaviour, pedal authority during side‑step manoeuvres, and autorotation characteristics with typical service weights. The rotor head’s articulation and damping were tuned to reduce ground resonance and to keep cockpit vibration within acceptable limits. These results guided refinements to blade construction and control linkage geometry before fleet introduction.

By the mid‑1940s, the single‑main‑rotor, tail‑rotor configuration had achieved practical dominance for utility helicopters. The Sycamore’s three‑bladed rotor provided a sensible balance among lift, vibration, and mechanical complexity; the tail rotor, set to give strong yaw authority, made pedal control intuitive and reliable across wind conditions and weights. These choices were conservative in the best sense: they favored the stable and maintainable over the exotic.

Rotorcraft Engineering: Mechanics, Systems, and Maintainability

The Sycamore’s principal technical virtue was its balance: a rotor and transmission tailored to a dependable powerplant, systems arranged for maintenance, and controls that communicated clearly to the pilot. The fully articulated rotor—with distinct flapping and lead‑lag hinges and a feathering mechanism—managed loads while allowing responsive control. The mast and head geometry were engineered to reduce vibration transmitted to the cabin, an important consideration for crew endurance and instrument readability.

Power came from an Alvis Leonides radial engine—a reliable, air‑cooled piston unit well understood by British mechanics. Placing the engine forward aided balance and simplified access. The transmission included reduction gearing and a freewheel unit to permit autorotation, while clutches and couplings were designed for predictable engagement and service. Fuel, oil, and cooling flows were routed with inspection in mind; line‑replaceable units were prioritized wherever feasible.

Rotor Dynamics and Control Harmony

Fully articulated rotors allow each blade to flap and lead‑lag relative to the hub, accommodating asymmetries in lift and inertia as the disc rotates. Proper damping in these hinges, coupled with tuned pitch‑link stiffness, prevents divergent oscillations and preserves crisp cyclic response. In service, this translated to small, steady control inputs in the hover and predictable transitions into forward flight—qualities repeatedly noted by crews during winch operations and confined‑area landings.

Autorotation and Energy Management

The freewheel unit decoupled the engine during failure, allowing blades to maintain rpm by airflow alone. Training syllabi emphasized quick lowering of the collective to capture rotor energy, steady attitude control to manage airspeed, and a flare to convert speed back into lift near touchdown. The Sycamore’s rotor inertia, blade aerofoil choice, and control gearing made this sequence teachable and repeatable, an essential ingredient in building confidence.

Key Engineering Features

- Fully Articulated Rotor: Flapping and lead‑lag hinges deliver stability across conditions

- Alvis Leonides Radial: A proven, maintainable powerplant with robust cooling

- Autorotation Capability: Freewheel unit supports safe engine‑out procedures

- Access‑First Layout: Panels and line‑replaceable units speed servicing

- Versatile Cabin: Configurable doors and fittings for rescue, liaison, and transport

The fuselage was a study in pragmatism. The cabin accepted stretchers, equipment, or passengers with minimal reconfiguration. Fixed landing gear provided simplicity and resilience on unprepared surfaces. Doors and fittings were arranged for winch operations and rapid loading. The overall design emphasized ruggedness and access: qualities that reduce downtime and increase mission availability.

Military Service and Operations: Search, Liaison, and Rescue

Entering Royal Air Force service in the early 1950s, the Sycamore quickly proved its worth in search and rescue, communications, and liaison duties. Its ability to hover steadily, operate from limited sites, and accept role equipment like winches made it an asset for missions where fixed‑wing aircraft could not contribute directly. Reliability mattered more than record‑setting performance. Line crews learned that the helicopter would start, lift, and hold station with the steadiness that turns a task into a procedure rather than a gamble.

Naval operations asked different questions—deck handling, salt exposure, and compact footprints. The Sycamore’s conservative systems and accessible maintenance points supported these demands; its responsiveness in the hover and predictable yaw authority simplified shipboard operations for trained crews. Across services, the type’s virtue was consistency: it did what was asked, repeatedly.

Casevac and Remote Access

Helicopters proved their worth where terrain and distance made ground evacuation slow and dangerous. The Sycamore’s steady hover and cabin access enabled casualty evacuation and liaison work in austere environments. The aircraft converted pilot discipline and crew coordination into minutes saved—an operational value that does not show in top‑speed tables but matters disproportionately in the field.

Operational notes emphasized crew coordination, particularly in search and rescue: the pilot’s small, continuous inputs kept the hover stable; the crewman at the door directed winch operations with agreed hand signals and clear voice procedures; and the aircraft’s systems tolerances—temperatures, pressures, and electrical loads—stayed within limits when run by the book. The Sycamore rewarded this discipline with repeatable outcomes.

Civil Uses and Export Success

Helicopter utility does not stop at the gate. Civil operators used the Sycamore for survey, liaison, training, and light transport. Reliability and access made it attractive for organizations stepping into rotary‑wing operations, where a conservative design and a straightforward maintenance manual were advantages in their own right. Exports to allied air arms and civil operators broadened the type’s footprint and established Britain’s credibility as a helicopter producer.

Technical Characteristics (Representative)

While marks and equipment varied, representative characteristics convey the aircraft’s practical envelope: a three‑bladed, fully articulated main rotor; a tail rotor providing firm yaw authority; a single air‑cooled radial engine in the 500‑plus horsepower class; useful load sufficient for crew, equipment, or stretchers depending on fit; and endurance appropriate to search, liaison, and training missions. The emphasis across variants remained on reliability over headline extremes.

Comparisons: Contemporary British and Allied Rotorcraft

Comparisons clarify strengths and limits. Against contemporaries derived from early American designs, the Sycamore stood out for maintainability and predictable handling. Westland’s early licensed types, and later indigenous developments, pursued similar reliability while adding power and, eventually, turbine propulsion in subsequent generations. The Sycamore’s fully articulated head and conservative systems distinguished it as a steady worker rather than a record‑setter—precisely what Britain needed to build a rotary‑wing practice sustained by procedure and training.

Legacy and Influence on British Aviation

The Sycamore’s legacy is method more than spectacle. It demonstrated how to embed helicopters within British military and civil practice: with training that emphasized procedures and teamwork; with maintenance that valued access and documentation; and with manufacturing that respected geometry and standards. Those habits transitioned naturally into subsequent British rotorcraft, where more power and capability were integrated without abandoning reliability.

Beneath that method lies a wider lesson: rotary‑wing flight succeeds when engineering discipline meets human discipline. The Sycamore taught crews to trust a new category of aircraft by behaving consistently and by rewarding attention to checklists, limits, and coordination.

German Helicopter Development and Wartime Influence

The Germans are not neglected in the book, with a full chapter on Focke Achgellis, Dobblehoff, Liore et Olivier etc. Hanna Reitsch and her test flights on the FW61 are included. Wartime German helicopter production is included and its influence on American and British helicopter development.

The Focke-Achgelis Fa 223 Drache represented one of the most advanced helicopter designs of the wartime period, demonstrating the potential of twin-rotor configurations. The book's coverage of German helicopter development provides context for understanding how British designers evaluated different design approaches and incorporated lessons learned from international developments. This international perspective demonstrates the collaborative nature of helicopter development, where insights from different nations contributed to the evolution of rotorcraft technology.

For comprehensive coverage of German aviation development during this period, see German Aircraft in the Great War 1914-1918, which provides foundational understanding of German aviation engineering traditions that influenced helicopter development. The book's coverage of German helicopter development demonstrates how wartime requirements accelerated technical development and how post-war analysis of German achievements informed subsequent designs.

Cierva Operations and Royal Air Force Service

The flight of Cierva and Reggie Brie from Italian cruisers is highly detailed in the book, providing comprehensive coverage of early naval rotorcraft operations. This documentation demonstrates how rotorcraft demonstrated their potential for naval operations, with autogyros proving capable of operating from shipboard platforms. These early naval operations established procedures and techniques that would influence subsequent naval helicopter development.

The book covers the history of the Cierva C30 in Royal Air Force service including the radar calibration flights and the 1943 dogfight of Norman Hill in his Rota I. This is the first published description in any book of this remarkable event. Hill had been intercepted over Hawkinge by two FW190s and by various manoeuvres survived to tell the tale. This documented incident demonstrates the operational versatility of autogyros and their ability to operate effectively in challenging circumstances, including combat situations where their unique flight characteristics provided advantages.

The Cierva C30's service in radar calibration flights demonstrates how rotorcraft contributed to military operations beyond their primary roles. The aircraft's ability to hover and operate at precise altitudes made it valuable for radar calibration and testing, establishing roles that would continue with helicopters. This operational history demonstrates how rotorcraft capabilities were recognized and exploited for various military applications beyond their initial design intent.

Manufacturing and Quality Assurance

Even in modest production runs, quality is a manufacturing habit: jigs that preserve alignment, inspection notes that travel with each airframe, calibrated tools checked on schedule, and surface finishes maintained to prevent premature corrosion and vibration. The Sycamore programme adopted these habits from fixed‑wing practice and adapted them to the unique demands of dynamic rotor systems. By doing so, it protected handling and reliability—the very attributes that defined the type in service.

The book's comprehensive documentation of manufacturing processes and quality assurance demonstrates how British aviation industry standards were applied to helicopter production. The emphasis on precision manufacturing, documented inspection procedures, and quality control systems ensured that Sycamore helicopters met the reliability standards necessary for operational service. This manufacturing discipline contributed significantly to the aircraft's operational success and established standards for subsequent British helicopter production.

For insights into British aviation manufacturing and industrial development, see Beardmore Aviation: The Story of a Scottish Industrial Giant's Aviation Activities, which provides comprehensive coverage of British aviation manufacturing processes and quality control systems. The industrial practices documented in works like Beardmore Aviation demonstrate the manufacturing culture that enabled successful helicopter production.

Pilot and Crew Experience

Accounts from training units and operational squadrons emphasized steady hover characteristics, clear pedal response, and control harmony that reduced workload in tasks such as winching. Autorotation practice was codified and repeatable; the helicopter’s systems gave appropriate warning through needles and temperatures when managed as taught; and emergency procedures were designed to be executed under stress. The aircraft’s character fostered confidence because it behaved like the manuals said it would.

Timeline and Evolution

Design studies that began in the final war years matured into a reliable service type in the early 1950s. Over time, refinements followed: detail improvements in rotor head components and control linkages for durability; system updates in radios and instrumentation; and cabin fittings optimized for rescue and liaison roles. These changes were incremental and justified by service experience—an approach that kept the airframe familiar while enhancing usefulness.

Aerodynamics and Cabin/Sightline Considerations

Hover and low‑speed work are visual disciplines as much as mechanical ones. The Sycamore’s cockpit glazing and seating heights afforded pilots the sightlines needed to hold references during winch and confined‑area operations. Fairings and fuselage contours were shaped for access and visibility first, with drag considerations secondary—an appropriate trade for the aircraft’s intended roles. Where forward speed mattered, smooth panel fit and careful maintenance kept vibration and parasitic drag low.

Training, Procedures, and Safety Culture

Rotorcraft training stressed procedural integrity: checklists that verified mechanical readiness; crew briefings that assigned clear roles for winch and rescue; and standardized communications. The Sycamore’s straightforward systems suited this culture well. It was an aircraft that became better, not worse, as crews became more disciplined, because it translated discipline directly into safer and more efficient operations.

Modern Legacy and Public Memory

Preserved Sycamores and museum exhibits keep the aircraft’s lessons alive. Visitors see not only a helicopter but a method: articulated rotor heads labelled to explain flapping and lead‑lag; transmission cut‑aways showing freewheel units for autorotation; and maintenance panels open to reveal access‑first design. Airworthy examples, where they exist, demonstrate the same steady hover and clear control feel that made the type trustworthy in service.

Conclusion: Foundation and Method

The Bristol Sycamore marked a true beginning for British helicopters by showing how to integrate the rotary‑wing idea into everyday operations. It did so not by chasing extremes but by prioritizing balance: a stable rotor system, a proven engine, accessible systems, and a cabin that admitted multiple roles. It is remembered today not only because it was first, but because it was trustworthy. In that reliability lies its influence: a method of design and use that later British helicopters extended with more power and new materials without abandoning the habits that made the Sycamore succeed.

MacKay's The Sycamore Seeds: The Early History of the Helicopter ensures that this remarkable story is preserved for future generations. The book's thorough research, detailed illustrations, and careful documentation create an authoritative resource that does justice to the Sycamore's achievements and contributions to helicopter progress. This scholarly work ensures that Britain's helicopter development receives the recognition it deserves.

The Sycamore's legacy extends beyond individual achievements to influence broader helicopter development. The aircraft's design features, operational experience, and manufacturing techniques contributed to subsequent helicopter development and operational procedures. The fundamental principles demonstrated in the Sycamore continue to influence helicopter design, demonstrating the lasting significance of these early achievements.

Further Reading and Related Works

For comprehensive coverage of British helicopter development and related topics, explore these authoritative works by Charles E. MacKay:

- The Sycamore Seeds: The Early History of the Helicopter — The definitive 219-page A5 work profusely illustrated with over 300 rare pictures and one colour, including unique drawings and illustrations published for the first time, covering helicopter development from Autogyros to 1950s helicopters

- Helicopter Development Pioneers: From Cierva's Autogyros to Modern Rotorcraft — Comprehensive analysis of vertical flight evolution, rotor aerodynamics, and control systems

- Bristol Sycamore: British Helicopter Development Pioneer — Detailed coverage of Britain's first production helicopter and its operational applications

- Sikorsky VS-300: The Helicopter Breakthrough — Comprehensive coverage of the first practical helicopter and its influence on subsequent developments

- Rotorcraft Military Applications: From Korea to Modern Warfare — Analysis of helicopter military operations and their evolution

- Captain Eric "Winkle" Brown: Test Pilot Biography — Includes coverage of British test pilot techniques and helicopter evaluation procedures

Related Articles

- Autogyro vs Helicopter: The Bridge to True Vertical Flight — Analysis of the transition from autogyros to helicopters

- Helicopter Development Pioneers — Comprehensive coverage of rotorcraft development from early experiments to modern helicopters

References

- Royal Air Force Museum — Aircraft Collection — Royal Air Force Museum

- Imperial War Museums — Aviation History Articles — Imperial War Museums

- FlightGlobal Archive — FlightGlobal