Adolf Rohrbach: The Metal Aircraft Revolution - Expert analysis by Charles E. MacKay

Introduction: The Engineering Visionary

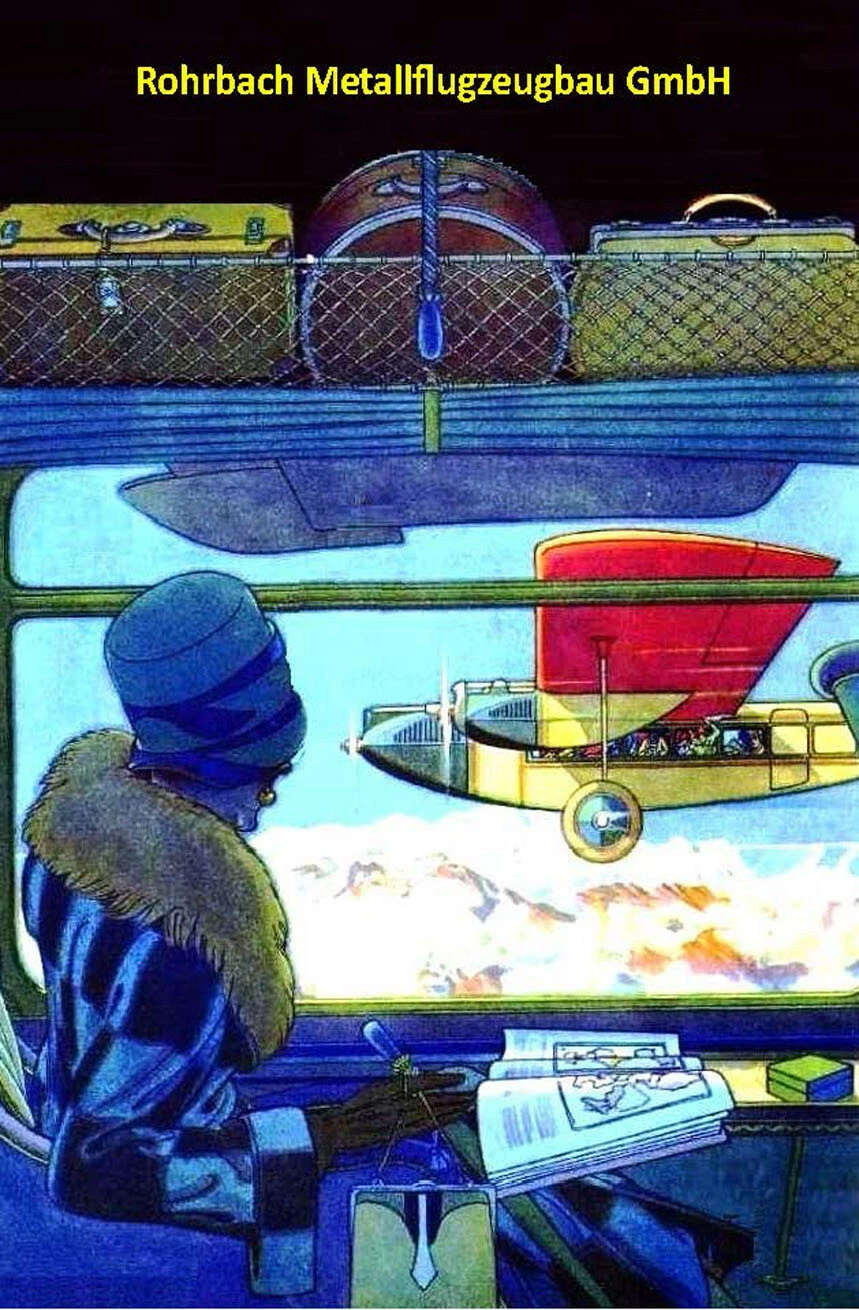

In the early 1920s, when most aircraft were still constructed from wood and fabric, a German engineer named Adolf Rohrbach was quietly revolutionizing aviation with metal construction techniques that would transform the industry. His innovative approaches to aircraft design and manufacturing established principles that remain fundamental to modern aviation, yet his contributions have often been overlooked in aviation history. This Enhanced Edition expands upon the complete story of Rohrbach's revolutionary contributions, incorporating deeper historical context, technical specifications, detailed analysis of his aircraft designs, comparisons with contemporary developments, and comprehensive examination of his modern legacy. Based on extensive archival research documented in Charles E. MacKay's authoritative work Adolf Rohrbach's Metal Airplanes: Rohrbach Metall-Flugzeugbau GmbH, this analysis presents the complete story of metal aircraft construction evolution with verified historical accuracy.

The book Adolf Rohrbach's Metal Airplanes presents newly researched history with 136 pages and over 200 photographs and drawings, many rare and obscure. Full details of every Rohrbach aeroplane and Rohrbach's design team are included, with rare drawings of Rohrbach's projected aeroplanes of 1931-32 which came to nothing. This comprehensive documentation ensures that Rohrbach's contributions to aviation development are properly understood, demonstrating how his innovations influenced aircraft design worldwide and established manufacturing principles still used today.

Rohrbach's work extended far beyond simple material substitution - he developed entirely new approaches to aircraft design that leveraged metal's unique properties while solving fundamental problems of strength, weight, and manufacturing efficiency. This comprehensive analysis reveals how this pioneering engineer's innovations influenced aircraft development worldwide and established manufacturing techniques still used today. From his early work at Zeppelin-Werke Staaken during World War I to his groundbreaking flying boat designs of the 1920s, Rohrbach consistently demonstrated how engineering excellence could overcome traditional limitations while establishing new standards for aircraft performance and reliability.

Historical Context: Industrial Shifts and Aviation Evolution

The development of metal aircraft construction occurred during a period of profound industrial and technological transformation. The early 20th century witnessed rapid advances in metallurgy, manufacturing techniques, and structural engineering that would enable metal aircraft construction. However, the transition from wood and fabric to metal construction required fundamental rethinking of aircraft design principles and manufacturing methods. The industrial context of post-World War I Germany, with its advanced engineering capabilities and constrained resources, provided the environment where Rohrbach's innovations could flourish.

Post-war Treaty of Versailles restrictions on German aviation actually accelerated Rohrbach's innovations by forcing efficiency and innovation within constrained parameters. These limitations encouraged creative solutions that maximized performance from available materials and manufacturing capabilities. The economic constraints of post-war Germany, combined with restrictions on military aviation, drove innovation in civil aviation applications that would establish metal construction as the standard for advanced aircraft design. The industrial capabilities developed during wartime production—precision manufacturing, quality control systems, and engineering expertise—provided the foundation for Rohrbach's metal aircraft innovations.

The aviation industry of the 1920s was characterized by rapid expansion in civil aviation, with commercial airlines seeking larger, more capable aircraft for passenger and cargo transport. These requirements drove innovation in aircraft design, with metal construction offering advantages in structural efficiency, durability, and manufacturing scalability that were essential for commercial aviation development. The transition from military to civil aviation applications created opportunities for innovative designers like Rohrbach to demonstrate metal construction's advantages while establishing new standards for aircraft performance and reliability.

Early Career and Naval Background: Foundation for Innovation

Adolf Rohrbach's path to aviation innovation began in German shipbuilding, where he gained expertise in metal construction techniques and structural engineering. This maritime background provided crucial insights into stress analysis, material properties, and manufacturing methods that would prove invaluable when applied to aircraft design and construction. Shipbuilding's emphasis on structural integrity, corrosion resistance, and efficient manufacturing processes provided essential knowledge that Rohrbach would apply to aircraft design, demonstrating how expertise from one field could transform another.

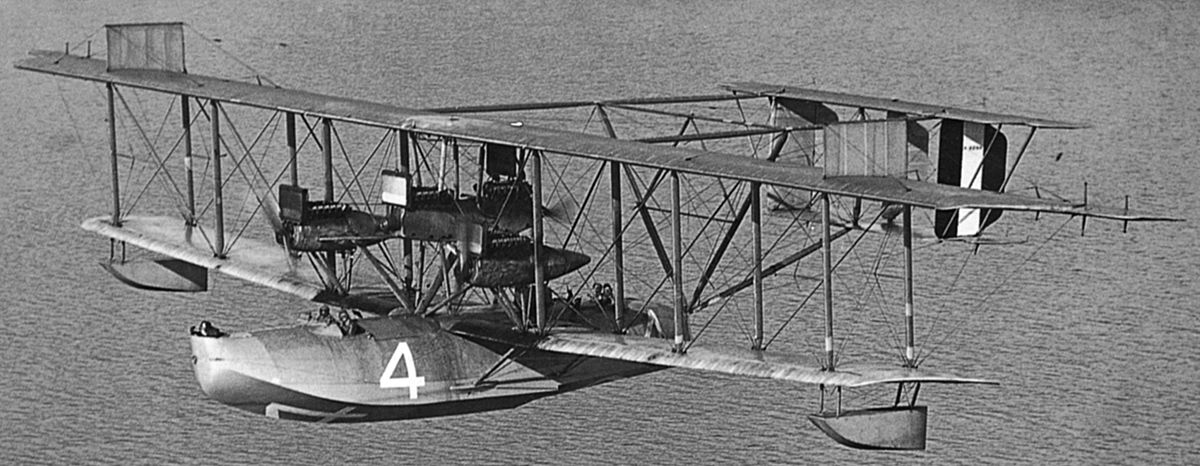

Working at Zeppelin-Werke Staaken during World War I, Rohrbach encountered the limitations of traditional wood and fabric aircraft construction. He recognized that metal construction could provide superior strength-to-weight ratios while enabling more sophisticated aerodynamic shapes impossible with conventional materials and construction methods. The book describes the revolutionary all-metal Zeppelin Staaken, demonstrating Rohrbach's early application of metal construction techniques to large aircraft design. This early work established principles that would guide subsequent metal aircraft development, demonstrating how metal construction could enable larger, more capable aircraft designs.

Rohrbach's engineering philosophy emphasized functional design optimized for manufacturing efficiency and operational performance. Unlike many contemporaries who focused on single-aircraft prototypes, he developed construction systems that could be applied across multiple aircraft types while maintaining structural integrity and performance characteristics. This systematic approach to aircraft design established patterns that would influence subsequent aircraft development, demonstrating how engineering principles could be applied across different aircraft types and applications.

Revolutionary Metal Construction Techniques: Stressed-Skin Innovation

Rohrbach's metal aircraft construction techniques represented a fundamental departure from traditional methods. His stressed-skin design approach integrated structural elements with aerodynamic surfaces, creating aircraft that were simultaneously stronger, lighter, and more aerodynamically efficient than conventional wood and fabric designs. The stressed-skin concept, where the outer skin contributes to structural strength rather than merely covering a framework, represented a revolutionary approach to aircraft construction that would become standard for modern aircraft design.

The development of specialized joining techniques allowed Rohrbach to create seamless metal structures without the weight penalties and stress concentrations associated with bolted or welded joints. These innovations enabled smooth external surfaces while maintaining structural integrity under operational loads and environmental conditions. The joining techniques developed by Rohrbach established principles for metal aircraft construction that would influence subsequent aircraft design, demonstrating how manufacturing methods could be optimized for both structural efficiency and aerodynamic performance.

Adolf Rohrbach travelled to America lecturing on "Stressed Skin construction," and this had a profound effect on Boeing, Douglas and Northrop, their aircraft types are illustrated in the book. These lectures demonstrated how Rohrbach's construction techniques could be applied to American aircraft development, with American engineers adapting Rohrbach's principles to their own aircraft designs. The influence of Rohrbach's stressed-skin construction techniques on American aviation development demonstrates how technical knowledge transfer accelerated aircraft development internationally, establishing metal construction as the global standard for advanced aircraft design.

Rohrbach's Key Innovations

- Stressed-Skin Construction: Integrated structure and aerodynamic surface

- Advanced Metal Joining: Specialized techniques for seamless construction

- Manufacturing Standardization: Interchangeable components and systematic production

- Quality Control Systems: Systematic inspection and testing procedures

- Corrosion Resistance: Materials and treatments for marine environments

- Systematic Design Philosophy: Construction systems applicable across multiple aircraft types

Manufacturing standardization became a cornerstone of Rohrbach's approach, with interchangeable components and systematic production methods that reduced costs while improving quality control. This industrial approach to aircraft construction influenced manufacturing practices throughout the aviation industry worldwide. The emphasis on standardization and systematic production methods demonstrated how industrial engineering principles could be applied to aircraft manufacturing, establishing patterns that would influence subsequent aircraft production and enabling the scale of production required for commercial aviation development.

Quality control procedures developed by Rohrbach established standards for metal aircraft inspection and testing that ensured consistent performance and safety. These systematic approaches to manufacturing verification became industry standards that continue to influence modern aircraft production methods. The emphasis on quality control demonstrated how manufacturing discipline could ensure aircraft reliability while enabling commercial aviation operations that required consistent performance and safety standards.

Rohrbach Aircraft Designs: Complete Aircraft Lineage

The book provides full details of every Rohrbach aeroplane and Rohrbach's design team. The second part of the book describes every Rohrbach design: the revolutionary all-metal Zeppelin Staaken, the Rohrbach seaplanes, including the Rodra, RoV Rocco, Beardmore Inflexible and Inverness, Robbe, Roland, Rofix fighter, Romar and the Rostra supported by rare drawings and photographs. This comprehensive coverage demonstrates how Rohrbach's metal construction techniques were applied across diverse aircraft types, from large bombers to small fighters, establishing the versatility of metal construction while demonstrating how systematic design principles could be applied across different aircraft applications.

The Rohrbach seaplanes represented significant achievements in metal aircraft construction, demonstrating how metal construction techniques could provide crucial advantages for marine aviation operations. The Rodra, RoV Rocco, Robbe, Roland, Romar, and Rostra designs incorporated advanced hull shapes, efficient wing structures, and innovative powerplant installations that demonstrated metal construction's advantages for flying boat applications. These aircraft designs established German aviation technology leadership while demonstrating the commercial viability of advanced metal aircraft construction for commercial aviation applications.

The Beardmore Inflexible and Inverness, built under licence in Britain, demonstrated how Rohrbach's construction techniques could be applied internationally. These aircraft incorporated Rohrbach's metal construction principles while adapting to British manufacturing capabilities and operational requirements. The licensing agreements that enabled these aircraft demonstrated how technical knowledge transfer accelerated aircraft development internationally, establishing metal construction as the global standard for advanced aircraft design.

The Rofix fighter represented Rohrbach's application of metal construction techniques to military aircraft design. This fighter design demonstrated how metal construction could provide advantages for high-performance military aircraft, with structural efficiency and aerodynamic performance that exceeded contemporary wood and fabric designs. The Rofix design demonstrated how Rohrbach's construction principles could be applied across different aircraft types and applications, establishing the versatility of metal construction while demonstrating systematic design principles.

The Rohrbach Roland: Pinnacle of 1920s Design

The Rohrbach Roland represented the pinnacle of 1920s flying boat design, incorporating advanced hull shapes, efficient wing structures, and innovative powerplant installations. This aircraft demonstrated how metal construction could enable larger, more capable flying boats with improved performance and operational reliability. The Roland's design incorporated Rohrbach's stressed-skin construction techniques, demonstrating how metal construction could provide structural efficiency while enabling sophisticated aerodynamic designs.

The book describes the growth of Luft Hansa and Deruluft (Deutsch-Russische Luftverkehrs A.G., or Deruluft) flying Rohrbach types and all the aircraft which were used by both companies. These commercial aviation applications demonstrated how Rohrbach's metal aircraft could support commercial airline operations, with the Roland and other Rohrbach types serving Luft Hansa and Deruluft routes. The commercial success of Rohrbach aircraft in airline service validated metal construction's advantages for commercial aviation, demonstrating reliability and operational efficiency that supported commercial airline development.

Adolf Hitler used a Rohrbach Roland in his 1932 election campaign which was flown by Hans Baur, and this is featured in the book, together with Baur, Hitler and the Rohrbach Roland. This historical incident demonstrates how Rohrbach aircraft were recognized for their capabilities and reliability, with the Roland's performance characteristics making it suitable for important political missions. The use of Rohrbach aircraft in political campaigns demonstrated how metal construction had established aircraft reliability and performance standards that supported diverse aviation applications.

Lipetsk (also known as Lipetskiy, Lipetsky, Shakhm 10, and Lipetsk West) in Russia became the test centre for the Luftwaffe, and the Rohrbach Roland airliner was tested there as a bomber. The book describes how the Roland was evaluated for military applications, demonstrating how civil aircraft designs could be adapted for military use. This testing demonstrated how metal construction provided structural efficiency and performance characteristics that supported both civil and military aviation applications, establishing the versatility of metal aircraft construction.

Patent Disputes and Legal Challenges

The first part of the book deals with the Rohrbach Company and Adolf Rohrbach, and it describes for the first time the patent action by Rohrbach against Claude Dornier which Rohrbach lost. This patent dispute demonstrates how intellectual property issues influenced aircraft development during this period, with competing claims to metal construction innovations creating legal challenges that affected aircraft development. The patent dispute reveals how technical innovation occurred in a competitive environment where legal protection for innovations was essential for commercial success.

The patent dispute between Rohrbach and Dornier reflected the competitive nature of metal aircraft development during the 1920s, with multiple designers working on similar problems and developing competing solutions. The legal resolution of patent disputes established frameworks for intellectual property protection that would influence subsequent aircraft development, demonstrating how legal systems influenced technical innovation and commercial competition in aviation development.

Civil Aviation Development: Luft Hansa and Deruluft

The book includes descriptions of the founding of Luft Hansa, Deruluft (Deutsch-Russische Luftverkehrs A.G., or Deruluft) and the finances of the Weimar Republic and the growth of German civil aviation directed by Hans von Seekt. These descriptions demonstrate how Rohrbach's aircraft contributed to German civil aviation development, with commercial airlines utilizing Rohrbach types for passenger and cargo transport. The growth of German civil aviation during the 1920s demonstrated how metal aircraft construction supported commercial aviation expansion, with Rohrbach aircraft providing the reliability and performance required for commercial airline operations.

The financial context of Weimar Republic aviation development influenced Rohrbach's company operations, with economic constraints affecting aircraft development and production. The book explains how the demise of the company was due to the economic collapse of Germany and the Depression, demonstrating how economic factors influenced aircraft development and company operations. The economic challenges encountered by Rohrbach's company revealed how aircraft development depended on economic stability and commercial viability, with economic factors affecting technical innovation and commercial success.

The principal shareholders—the German Reich and the German insurance companies—wanted Adolf Rohrbach removed, and the company was then liquidated. This corporate history demonstrates how business and political factors influenced aircraft development and company operations, with corporate governance decisions affecting technical innovation and commercial viability. The liquidation of Rohrbach's company revealed how economic and political factors could influence aircraft development, demonstrating how technical innovation occurred within broader economic and political contexts.

Projected Designs: Unbuilt Innovations

The book includes rare drawings of Rohrbach's projected aeroplanes of 1931-32 which came to nothing. These projected designs demonstrate how Rohrbach continued to innovate despite economic challenges, developing advanced aircraft concepts that were never built due to economic constraints and company liquidation. These unbuilt designs reveal how technical innovation continued even when economic conditions prevented production, demonstrating how engineering creativity persisted despite commercial challenges.

The projected designs provide insights into Rohrbach's design philosophy and technical vision, revealing how he continued to develop advanced aircraft concepts even as his company faced economic challenges. These designs demonstrate how engineering innovation could continue despite commercial difficulties, with technical creativity persisting even when economic conditions prevented production. The unbuilt designs reveal how Rohrbach's technical vision extended beyond immediate commercial applications to encompass advanced aircraft concepts that would influence subsequent aircraft development.

American Influence: Boeing, Douglas, and Northrop

Adolf Rohrbach's lectures on "Stressed Skin construction" in America had a profound effect on Boeing, Douglas and Northrop, and their aircraft types are illustrated in the book. This influence demonstrates how Rohrbach's construction techniques accelerated American aircraft development, with American engineers adapting Rohrbach's principles to their own aircraft designs. The transfer of technical knowledge from Germany to America demonstrates how international cooperation accelerated aircraft development, establishing metal construction as the global standard for advanced aircraft design.

Boeing's adoption of stressed-skin construction influenced subsequent aircraft development, with Boeing aircraft incorporating metal construction techniques that traced their origins to Rohrbach's innovations. The Boeing 247 and subsequent aircraft designs demonstrated how stressed-skin construction could provide structural efficiency and aerodynamic performance advantages that supported commercial aviation development. Douglas aircraft similarly incorporated metal construction principles, with DC series aircraft establishing metal construction as the standard for commercial airliners.

Northrop's application of Rohrbach's construction techniques demonstrated how stressed-skin construction could be applied to different aircraft types and applications. Northrop aircraft designs incorporated metal construction principles that provided structural efficiency and performance advantages, demonstrating how Rohrbach's innovations influenced diverse aircraft development programs. The influence of Rohrbach's construction techniques on American aircraft development demonstrates how technical knowledge transfer accelerated aircraft development internationally, establishing metal construction as the global standard for advanced aircraft design.

Technical Specifications and Design Details

Rohrbach's metal aircraft construction techniques provided specific technical advantages that influenced aircraft performance and manufacturing efficiency. The stressed-skin construction approach enabled thinner wing sections and improved aerodynamic efficiency compared to conventional wood and fabric designs. The metal construction techniques developed by Rohrbach enabled larger aircraft designs with improved structural efficiency, demonstrating how material and construction method improvements could enable aircraft capability advances.

The structural efficiency of Rohrbach's metal construction techniques enabled aircraft designs with superior strength-to-weight ratios compared to conventional construction methods. The integration of structural elements with aerodynamic surfaces reduced weight while maintaining structural integrity, demonstrating how engineering innovation could improve aircraft performance through construction method improvements. The technical advantages of metal construction enabled aircraft designs that exceeded the capabilities of conventional construction methods, establishing metal construction as the standard for advanced aircraft design.

Manufacturing advantages of Rohrbach's construction techniques included standardized production methods that reduced costs while improving quality control. The systematic approach to aircraft construction enabled production efficiencies that supported commercial aviation development, demonstrating how manufacturing method improvements could enable aircraft capability advances. The manufacturing advantages of metal construction supported commercial aviation expansion by enabling aircraft production at scales required for commercial airline operations.

Comparative Analysis: Rohrbach vs Contemporary Designs

Comparisons with contemporary aircraft designs reveal how Rohrbach's metal construction techniques provided advantages over conventional wood and fabric designs. The structural efficiency of metal construction enabled aircraft designs with superior performance characteristics, demonstrating how material and construction method improvements could enable aircraft capability advances. The performance advantages of metal construction established it as the standard for advanced aircraft design, with subsequent aircraft development incorporating metal construction principles.

Comparisons with other metal aircraft designers, including Dornier and Junkers, reveal how different approaches to metal construction developed during this period. The patent dispute between Rohrbach and Dornier reflected competing approaches to metal aircraft construction, with different designers developing similar solutions to common technical challenges. These comparisons demonstrate how technical innovation occurred in a competitive environment where multiple designers worked on similar problems and developed competing solutions.

The commercial success of Rohrbach aircraft compared to contemporary designs demonstrates how metal construction provided advantages for commercial aviation applications. The reliability and performance of Rohrbach aircraft supported commercial airline operations, demonstrating how technical innovation could enable commercial success. The commercial advantages of metal construction established it as the standard for commercial aviation, with subsequent aircraft development incorporating metal construction principles.

Manufacturing and Industrial Context

Rohrbach's emphasis on manufacturing standardization and systematic production methods demonstrated how industrial engineering principles could be applied to aircraft manufacturing. The systematic approach to aircraft construction enabled production efficiencies that supported commercial aviation development, demonstrating how manufacturing method improvements could enable aircraft capability advances. The manufacturing principles established by Rohrbach influenced subsequent aircraft production, establishing patterns for aircraft manufacturing that would support commercial aviation expansion.

The quality control systems developed by Rohrbach established standards for aircraft manufacturing that ensured consistent performance and safety. These manufacturing standards influenced subsequent aircraft production, establishing patterns for quality control that would support commercial aviation operations requiring consistent performance and safety standards. The emphasis on manufacturing quality demonstrated how production discipline could ensure aircraft reliability while enabling commercial aviation operations.

For insights into British aviation manufacturing and industrial development that incorporated Rohrbach innovations, see Beardmore Aviation: The Story of a Scottish Industrial Giant's Aviation Activities, which provides comprehensive coverage of British aviation manufacturing processes and quality control systems. The Beardmore Inflexible and Inverness, built under licence from Rohrbach, demonstrate how British manufacturers adapted Rohrbach's construction techniques to British manufacturing capabilities and operational requirements.

Modern Legacy and Enduring Influence

Modern aircraft construction continues to rely on principles established by Adolf Rohrbach nearly a century ago. Contemporary manufacturing techniques, structural design approaches, and quality control procedures all trace their origins to innovations pioneered by this German engineering visionary. The stressed-skin construction techniques developed by Rohrbach remain fundamental to modern aircraft design, demonstrating how engineering innovation can establish principles that endure for generations.

The influence of Rohrbach's construction techniques on American aircraft development demonstrates how technical knowledge transfer accelerated aircraft development internationally. Boeing, Douglas, and Northrop aircraft designs incorporated metal construction principles that traced their origins to Rohrbach's innovations, establishing metal construction as the global standard for advanced aircraft design. The international influence of Rohrbach's innovations demonstrates how technical knowledge can accelerate aircraft development across national boundaries, establishing global standards for aircraft design and manufacturing.

The manufacturing principles established by Rohrbach influenced subsequent aircraft production, establishing patterns for aircraft manufacturing that would support commercial aviation expansion. The emphasis on standardization, quality control, and systematic production methods established manufacturing principles that continue to influence modern aircraft production, demonstrating how engineering innovation can establish manufacturing standards that endure for generations.

MacKay's Adolf Rohrbach's Metal Airplanes: Rohrbach Metall-Flugzeugbau GmbH ensures that Rohrbach's contributions to aviation development are properly preserved. The book's thorough research, detailed illustrations, and careful documentation create an authoritative resource that does justice to Rohrbach's achievements and contributions to aviation progress. This scholarly work ensures that Rohrbach's innovations receive the recognition they deserve in aviation history.

Conclusion: The Enduring Legacy

Adolf Rohrbach stands as one of aviation's most influential yet underappreciated pioneers, whose revolutionary metal aircraft construction techniques fundamentally transformed the industry. His systematic approach to engineering problems and innovative manufacturing solutions established principles that remain central to modern aircraft development. From his early work at Zeppelin-Werke to his groundbreaking flying boat designs, Rohrbach consistently demonstrated how engineering excellence could overcome traditional limitations while establishing new standards for aircraft performance and reliability.

The influence of Rohrbach's construction techniques on American aircraft development demonstrates how technical knowledge transfer accelerated aircraft development internationally. Boeing, Douglas, and Northrop aircraft designs incorporated metal construction principles that traced their origins to Rohrbach's innovations, establishing metal construction as the global standard for advanced aircraft design. Today, as the aviation industry continues to evolve with new materials and manufacturing technologies, Adolf Rohrbach's legacy endures through the systematic approaches he established for aircraft design and construction. His vision of functional, efficient aircraft design continues to inspire engineers working to advance aviation technology for future generations.

Further Reading and Related Works

For comprehensive coverage of metal aircraft construction and related topics, explore these authoritative works by Charles E. MacKay:

- Adolf Rohrbach's Metal Airplanes: Rohrbach Metall-Flugzeugbau GmbH — The definitive 136-page work with over 200 photographs and drawings, many rare and obscure, including full details of every Rohrbach aeroplane and Rohrbach's design team, with rare drawings of projected aeroplanes

- Beardmore Aviation: The Story of a Scottish Industrial Giant's Aviation Activities — Includes coverage of British licence-built Rohrbach aircraft and British aviation manufacturing

- German Aircraft in the Great War 1914-1918 — Provides context for German aviation engineering traditions that influenced Rohrbach's development

- Adolf Rohrbach: Revolutionary Metal Aircraft Designer — Detailed coverage of Rohrbach's metal construction techniques

- Aviation Manufacturing and Wartime Production — Manufacturing context for metal aircraft construction development

Related Articles

- German Aircraft Great War Development — Context for German aviation engineering traditions

- Aviation Manufacturing: Wartime Production Revolution — Manufacturing context for aircraft development

References

- Royal Air Force Museum — Aircraft Collection — Royal Air Force Museum

- Imperial War Museums — Aviation History Articles — Imperial War Museums

- FlightGlobal Archive — FlightGlobal