A platform that grew: aerodynamic discipline meeting rising power and mission demands.

Introduction: An Airframe Built to Grow

Spitfire evolution is the story of a balanced airframe scaled through power, armament, and systems changes without losing core handling qualities. This article follows racing lineage, aerodynamic development, engine and cooling integration, marks progression, production realities, and operational use with a source-first focus on what changed, why it changed, and what remained consistent.

Racing Lineage and Aerodynamic Discipline

Supermarine’s Schneider experience delivered a culture of clean aerodynamics: tight cooling schemes, high surface quality, and efficient planforms. Racing seaplanes such as the S.6B demonstrated that drag could be systematically removed with flush rivets, careful fairings, and refined inlets and ducts. The elliptical wing — adopted for even lift distribution and low induced drag — gave the Spitfire headroom for growth. Early development paired aerodynamic discipline with practical access: gun bays and panels were integrated without compromising the essential cleanliness of the outer mold line.

Elliptical Wing: Theory into Practice

An elliptical lift distribution minimizes induced drag for a given span and lift. Real airframes must accommodate guns, landing gear, and structure; the Spitfire’s wing achieved a close approximation with a planform that preserved local thickness for structure and armament while maintaining low‑drag lift distribution. The result: high efficiency across the envelope and graceful stall behaviour prized by pilots.

Engines and Integration

From early Merlin fits onward, power increased with careful attention to cooling and drag. The fuselage, radiator housings, and intake geometry evolved with engines, preserving balance between power and aerodynamic cleanliness. Later marks incorporated higher‑power Merlins and, in some variants, Griffon engines, with corresponding refinements to cowl lines and cooling capacity. Throughout, the goal remained coherence: add capability without degrading handling or introducing unnecessary drag.

Marks, Armament, and Equipment

Eight wing‑mounted .303‑inch Brownings defined early marks, optimizing snapshot lethality in short engagements. As targets hardened and tactics changed, cannon fits were introduced with blister fairings and reinforced bays. Radios improved net discipline; navigation and oxygen systems matured as operating altitudes and mission profiles broadened. The wing structure — a hallmark of the design — accommodated these shifts with minimal aerodynamic penalty.

Armament Tuning and Harmonization

Gunnery effectiveness depended on harmonization ranges and pattern choice. Units tuned convergence for expected engagement distances, balancing dense central patterns against broader spread. The Spitfire’s wing made such tuning practical, with access panels designed for rapid armament servicing under operational tempo.

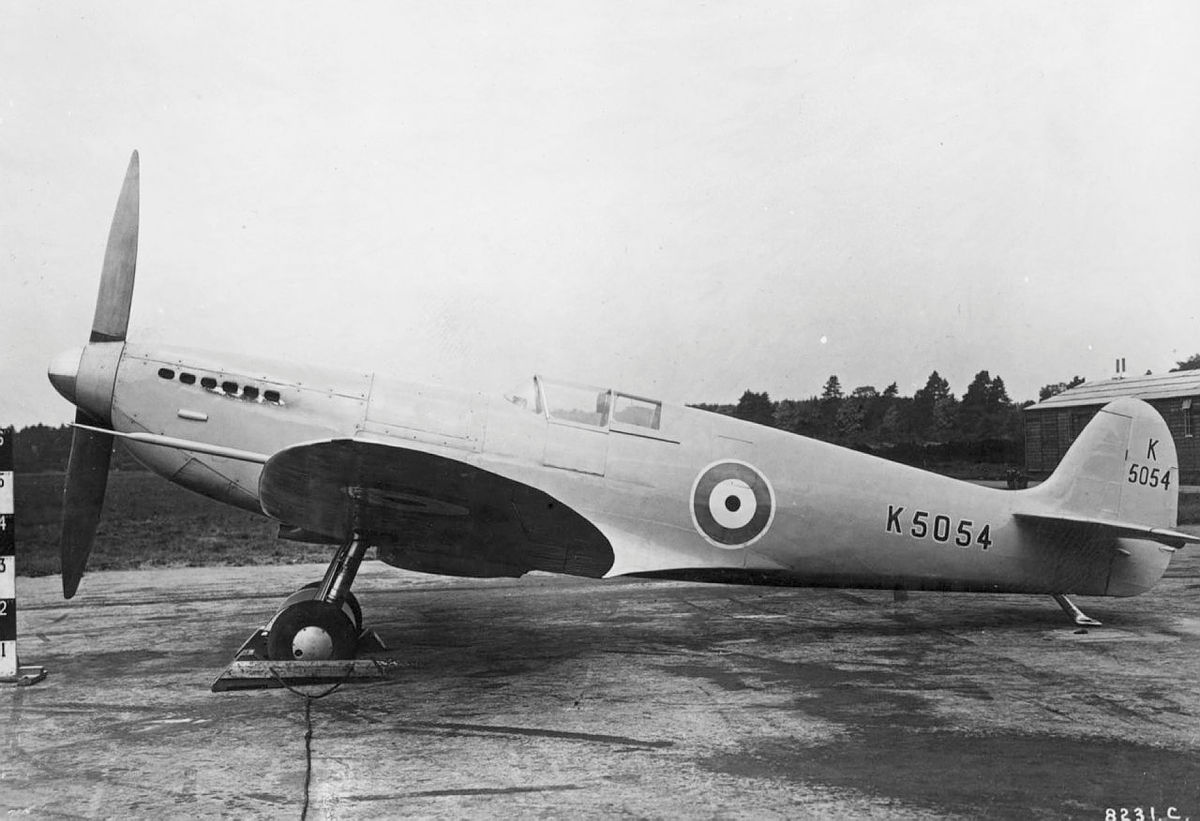

Prototype, Testing, and Refinement

From K5054 onward, flight testing validated the concept and tuned stability, visibility, and systems. Refinements focused on canopy visibility, control harmony, and cooling margins. Each change was documented and weighed against aerodynamic cost and mass growth. The result: an aircraft that kept its signature handling while real‑world needs drove incremental improvements — measured, not improvised.

Manufacturing and Workforce

Elliptical wings demanded precision jigs and trained labour. Stressed‑skin and flush‑riveted construction placed quality demands on shops; metrology and documentation underpinned repeatability across sites. Industrial mobilization brought sub‑assembly strategies and inspection regimens that preserved shape fidelity and structural integrity while scaling output. The workforce — increasingly diverse as the war progressed — internalized inspection culture with traveller sheets, gauge logs, and calibrated‑tool control.

Combat Doctrine and Comparisons

Operationally, the type balanced manoeuvre, sufficient speed, climb, and reliable fire. British doctrine emphasized altitude advantage, teamwork, and short, decisive engagements that exploited the Spitfire’s agility and harmonized firepower. Escorts and interceptors applied different grammar: interception favored climb and positioning; escort favored disciplined formation and mutual support.

Comparisons: Hurricane, Spitfire, and Bf 109

Hawker’s Hurricane, with its robust structure and forgiving handling, excelled against bombers and in rough fields; the Spitfire offered higher aerodynamic efficiency and agility against fighters. Against the Bf 109, the Spitfire’s turning authority and visibility contrasted with the 109’s high‑lift devices and strong climb. Outcomes depended on pilot skill, starting energy, and tactical discipline more than on narrow headline statistics.

Pilot Accounts

Pilot reports consistently praised the Spitfire’s control harmony and predictable high‑alpha behaviour. They noted that brief, accurate fire and energy preservation won fights. Conversion notes cautioned against fixating on turn radius alone: altitude, sun, and teamwork remained decisive, with the airframe providing the means to capitalize on those choices.

Evolution Without Losing Balance

Spitfire marks gained power, range of armament options, and equipment while maintaining the airframe’s core virtues. That growth path marks the design as exceptional: it accepted upgrades without becoming blunt or unstable — a testament to foundation decisions on wing planform, structural efficiency, and engine integration. Few airframes accepted as much growth with so little loss to pilot‑loved handling.

Legacy and Influence

The Spitfire’s evolution validated design as an extensible framework, not a frozen artifact. Its lessons — aerodynamic discipline, measured integration, manufacturing quality, and pilot‑centred handling — informed post‑war practice and remain instructive wherever aircraft are asked to grow capability without surrendering their core strengths.

Development Timeline: 1930s Prototypes to Late‑War Marks

Pre‑war racing informed the first studies; Air Ministry specifications shaped prototypes; and early service uncovered operational realities that fed back into design. As power and mission demands grew, the airframe absorbed new engines, armament, and equipment while keeping its signature handling. This continuity across years is what “evolution” means in practice: each change was justified by operational need and verified in flight test before fleet adoption.

Early Prototypes and Lessons

Prototype flights confirmed aerodynamic assumptions and exposed practical considerations: canopy visibility under operational workloads, cooling margins across weather and altitude, and maintainability during quick turnarounds. The project culture remained steady — measure, adjust, document — which would characterize later mark introductions.

Mid‑War Marks and Operational Refinement

As missions diversified, aircraft incorporated revised cooling arrangements, armament options, and radio/navigation improvements appropriate to the tactical environment. The principle was always the same: integrate without compromising control harmony or adding unnecessary drag. Where fairings and blisters were required for new equipment, their geometry was refined to preserve efficient flow.

Late‑War Marks and Power Growth

Late‑war variants brought increases in power and capability supported by incremental structural and systems changes. The aerodynamic discipline established at the outset made these changes tractable. Pilots still reported the qualities that defined the type: predictable behaviour near the limits and a sense that the aircraft responded as an extension of intent.

Industrial Mobilization and Quality Assurance

Meeting operational demand required more than design excellence; it required industrial organization that respected the design’s aerodynamic and structural intent. Precision jigs held critical geometry; inspection culture preserved it across shifts and sites. Documentation — travellers, gauge logs, torque charts — enabled consistency as output scaled. In this way, the aircraft’s performance in the air was protected by habits on the ground.

Metrology and Repeatability

Metrology ensured that components matched drawing and that assemblies aligned without undue stress. Surface finish and flush riveting safeguarded drag assumptions; control‑run checks and rigging fixtures preserved handling assumptions. The result was not simply quantity but quality at quantity.

Pilot Testimonies and Operational Notes

Pilots valued control harmony and the aircraft’s willingness to respond precisely near the edge of the envelope. Conversion notes emphasized energy management, teamwork, and firing discipline: brief, accurate bursts at harmonized ranges. Reports from interceptions highlighted climb and positioning as decisive factors; reports from escort emphasized formation integrity and mutual support. Across contexts, the airframe’s predictability enabled pilots to execute doctrine with confidence.

Expanded Comparisons: Strengths, Trades, and Outcomes

Comparisons are meaningful only when framed by mission, starting energy, and pilot skill. The Hurricane’s robust structure and benign handling rewarded squadrons tasked with bomber interception and operations from austere fields. The Spitfire’s aerodynamic efficiency and armament arrangement favored short, decisive fighter engagements. Against the Bf 109, outcomes often reflected altitude advantage, sun angle, and tactical discipline; the aircraft’s particular strengths provided the means to convert those advantages into results. The Spitfire’s evolution sustained these strengths as power rose and missions diversified.

Modern Legacy: Restoration, Training, and Cultural Memory

Preserved examples and restorations keep the type’s lessons alive: aerodynamic cleanliness, careful integration, and rigorous documentation. Training organizations and museums use the aircraft’s story to illustrate how design and industry must align to produce reliable combat power. The airplane remains a touchstone for pilots who value control harmony — a quality that cannot be retrofitted into a rushed design.

Systems Architecture: Hydraulics, Electrics, and Reliability

Behind aerodynamic lines sat systems chosen for robustness and serviceability. Hydraulic circuits actuated undercarriage and flaps with redundancy appropriate to the era, while manual procedures were codified to handle failures. Electrical systems fed ignition, radios, and instrumentation through straightforward looms routed for access and protected against chafing. These choices reflected an operational ethos: keep systems simple enough to diagnose on a dispersal pan and rugged enough to accept field repairs without specialized equipment. The result was tempo—sorties preserved by systems that cooperated with maintainers under pressure.

Gunsight Evolution and Fire Control Discipline

Fire control evolved from fixed‑sight marksmanship to gyro‑assisted aiming. Early reflector sights required pilots to compute lead and closure from experience and training; later gyro gunsights assisted by stabilizing the reticle and estimating lead based on target wingspan and turn rate inputs. The Spitfire’s stable gun platform and predictable pitch response helped both systems by minimizing transient errors during short, disciplined bursts at harmonized ranges. Units codified approach angles and break‑off criteria, ensuring that ammunition expended translated into results rather than waste.

Oxygen, Heating, and Environmental Discipline

Operations at altitude required oxygen systems, canopy management, and heating provisions that worked in cold, thin air. Procedures emphasized pre‑flight checks of regulators, flow, and mask integrity; canopy sealing and demisting; and glove discipline to preserve tactile sensitivity on the controls. High‑altitude marks introduced pressurization where appropriate, demanding additional attention to sealing, structural loads, and emergency procedures. These measures were not luxuries but mission enablers: reconnaissance, interception, and escort profiles all depended on crews who could perform at altitude without distraction.

Materials, Surface Finish, and Corrosion Control

Surface finish quality and corrosion vigilance preserved aerodynamic assumptions over service life. Rivet flushness, puttied seams where appropriate, and clean paint ensured that boundary‑layer behaviour matched design intent. In maritime and coastal climates, thorough washing, inspection of joints, and sealing of vulnerable intersections prevented corrosion from eroding safety margins or distorting surface quality. The connection between shop practice and flight performance remained visible throughout the programme.

Supply Chain, Training, and Documentation

Production scale relied on a national network: primary factories, subcontractors, and transport linking assemblies to final lines. Training pipelines—both for pilots and maintainers—matured alongside: Operational Training Units prepared crews in tactics and aircraft handling; technical schools qualified riggers and fitters in inspection standards, torque values, and documentation. Traveller sheets and parts traceability ensured that when an airframe reached a squadron, it conformed to the geometry and systems configuration expected, with spares and manuals aligned to that standard.

Operational Cases: Learning in Contact

Fighter sweeps over occupied Europe underscored energy discipline: formations climbed to arrive with altitude in hand, struck in coordinated pairs or fours, and disengaged by plan rather than impulse when fuel dictated. Interceptions demanded tight controller‑pilot coordination; the aircraft’s climb and acceleration helped convert vectors into position. Close support in later campaigns required communication discipline with ground controllers, careful identification, and the restraint to preserve fuel and ammunition for decisive moments. In all roles, the aircraft’s predictable handling helped pilots translate doctrine into action.

Restoration Practice: Keeping the Method Alive

Modern restorations replicate wartime methods because those methods still produce the behaviour pilots expect. Jigs locate spars and frames; skins are fitted and riveted with attention to flushness; control runs are rigged to precise neutral and travel limits; and engine installations balance cooling with cowl integrity. The aim is not cosmetic fidelity alone but aerodynamic and handling fidelity: the same geometry, the same mass distributions, the same systems margins. When these are honored, the aircraft flies like a Spitfire, not merely a look‑alike.

Lessons With Contemporary Relevance

The programme exemplifies principles that remain valid: set a coherent aerodynamic and structural baseline; protect it with manufacturing discipline; evolve power and equipment in measured increments with test‑backed validation; and educate pilots and maintainers so the human system keeps pace with the machine. These lessons apply beyond aviation history; they define effective engineering in any field where performance, reliability, and human factors must align.

Aerodynamic Testing and Control Surface Refinements

Wind‑tunnel work and flight testing informed successive refinements to the aircraft’s outer mold line and control surfaces. As speeds increased, aileron effectiveness on early fabric‑skinned surfaces declined; metal‑skinned ailerons restored roll authority at higher dynamic pressures. Elevator and rudder balance and hinge arrangements guarded against over‑sensitivity and flutter, while trim systems were maintained as simple, reliable mechanisms. Even small surface details — fairing intersections, panel fit, and access‑door edges — were reviewed to protect drag assumptions established during prototype work.

Cooling inlets and exits were tuned for pressure recovery and exit‑area control, recognizing that adequate cooling with minimal drag penalty is a core determinant of sustained performance. The approach remained empirical but disciplined: test, document, and incorporate only those changes that proved their value in measured results.

Propellers, Supercharging, and Fuel Systems

Propeller evolution tracked engine power and altitude regimes. Early two‑ and three‑blade propellers gave way to constant‑speed units from established British manufacturers, allowing the engine to operate near optimal rpm across climb and cruise while improving acceleration out of the turn. As engines adopted higher boost with two‑speed and later two‑stage superchargers, blade count and planform geometry were revised to absorb power efficiently without undue noise or tip losses. These changes reinforced the aircraft’s energy advantages in climb and vertical manoeuvre.

Fuel systems began with float‑type carburetors that were vulnerable under negative g. Tactical workarounds — half‑roll then pull — were institutionalized in training, and a restrictor introduced by an RAE engineer mitigated fuel surge until improved systems arrived. The point is not the inconvenience, but the response: operational reality identified a constraint; engineering provided a timely, practical remedy; tactics were adjusted to maximize effectiveness meanwhile.

Theatres of War: Logistics and Adaptation

Operations across diverse theatres imposed new disciplines. Coastal climates demanded vigilance against corrosion; desert conditions required filtration and dust control; northern winters brought icing risks mitigated by procedures and equipment. Logistics determined tempo: spares provisioning, dispersal of aircraft across satellite fields, and the training of ground crews for local conditions were as decisive as any single performance metric. The airframe’s reliability and straightforward access to critical systems made it a cooperative partner for squadrons working at sustained operational pace.

Escort, sweep, and interception profiles varied by theatre, but the underlying grammar remained: maintain energy, use altitude, and fight briefly and decisively. Each mark introduced for a theatre respected these fundamentals while adding the range, communications, or environmental resilience appropriate to the task.

Training and Gunnery

Conversion syllabi stressed procedural discipline: cockpit checks, engine management, and pattern work that internalized throttle‑rudder coordination on the ground and in the climb. Gunnery instruction moved beyond simple marksmanship to tactical sighting — harmonization distances, lead computation with gyro sights, and the judgement to fire only when geometry promised results. The aircraft’s stability as a gun platform, particularly after the adoption of cannon and refined heating for reliability, made that judgement pay off.

Maintenance, Field Modifications, and Resilience

Squadron maintenance turned intent into reality. Rigging checks preserved control harmony; periodic inspection of control runs guarded against wear that could introduce play; engine monitoring and plug changes were conducted by the book to protect reliability. Field modifications — from local fairing tweaks to environmental protections — were tolerated when they served clear operational needs and did not threaten safety or performance. This practical, documented flexibility is one reason the aircraft remained serviceable under pressures that could have broken a less disciplined programme.

Post‑War Influence and Continuity

Post‑war, the aircraft’s lessons migrated into training curricula, restoration shops, and design studios. Engineers pointed to the type when explaining how aerodynamic cleanliness and structural honesty pay dividends across the envelope. Pilots referenced its control harmony when discussing the feel that fosters precision. Museum programs and flying collections preserved not only artifacts but practices — jigging, riveting standards, inspection — that keep the connection between drawing and performance visible to the public.

This continuity matters. It anchors public memory to the realities of design and labour. It also equips a new generation of engineers and maintainers to appreciate that the elegant solution is often the robust one, because it removes the unnecessary and gives margin back to the pilot.

Selected Technical Notes

- Elliptical planform aimed at near‑ideal lift distribution with practical allowances for structure and armament, protecting induced‑drag assumptions while enabling benign stall behaviour.

- Stressed‑skin structure with a torsion‑resistant forward box limited aeroelastic twist, preserving control authority at higher speeds and loadings.

- Cooling installations refined for pressure recovery and effective exit control, limiting drag growth as power and heat rejection increased.

- Propeller and supercharger evolution matched to climbing, escort, and interception regimes, sustaining energy advantages without sacrificing handling balance.

- Armament progression from rifle‑calibre batteries to cannon, supported by heating and feed improvements for reliability at altitude.

Related Books and Articles

- Supermarine Spitfire: Complete Development History

- Hawker Hurricane: Development

- Schneider Trophy Racing: Development

Conclusion

Evolution was earned, not accidental. The Spitfire’s balanced starting point, disciplined integration, and manufacturing quality allowed power and capability to grow without breaking what made it special. Its legend rests on engineering discipline that pilots could feel — and results that history recorded.

References

- Royal Air Force Museum — Aircraft Collection — Royal Air Force Museum

- Imperial War Museums — Aviation History Articles — Imperial War Museums

- FlightGlobal Archive — FlightGlobal