Original illustration (schematic): compact naval biplane outline with folding-wing cues (diagrammatic).

Introduction: Scottish Naval Aviation Innovation

The Beardmore W.B.III sits within the formative phase of British naval aviation during the First World War. As William Beardmore & Company expanded from heavy engineering into aviation, naval requirements drove design choices around deck handling, structure, and maintainability. This article examines W.B.III development, engineering features, and operational context using source material documented in Charles E. MacKay's Beardmore Aviation: The Story of a Scottish Industrial Giant's Aviation Activities, with linked references to Argus and related naval aviation pages.

Context and Origins: Beardmore's Entry into Naval Aviation

William Beardmore & Co., a Scottish industrial giant renowned for shipbuilding and steel manufacturing, diversified into aviation with a focus on naval requirements. The Beardmore W.B.III grew from British attempts to adapt fighter concepts to shipboard use, blending structural robustness with the constraints of early carrier operations. Its development sits within Clyde engineering culture—shipyards, steel, and precision manufacturing—that supplied parts, skills, and discipline to aviation manufacturing.

The book Beardmore Aviation provides comprehensive coverage of Beardmore's aviation activities from 1913 to 1930, including detailed information on aircraft production, aero-engines, airships, and an in-depth history of the first aircraft carrier H.M.S. Argus. The evolution of the Sopwith aircraft produced by Beardmore, including Camel operations off cruisers and the carriers Argus and Furious, demonstrates the company's commitment to naval aviation requirements.

Beardmore's entry into naval aviation was not accidental but strategic. The company's expertise in shipbuilding, metalworking, and large-scale engineering positioned them perfectly to address the unique challenges of naval aircraft design. Their facilities at Dalmuir, Clydebank and Parkhead, Glasgow provided the industrial infrastructure necessary for aircraft production, while their shipyard experience informed their understanding of maritime operations and requirements.

The W.B.III emerged during a period when naval aviation was rapidly evolving. The Royal Naval Air Service (RNAS) required aircraft capable of operating from ships, with features including folding wings, reinforced structures, and specialized equipment for deck operations. Beardmore's response to these requirements demonstrated their engineering capability and understanding of naval operational needs.

Engineering Features: Naval Requirements and Design Solutions

Naval fighters demanded arresting robustness, corrosion resistance, and compact footprints. Folding wings, reinforced undercarriages, and fittings for deck-handling distinguished the type from land-based peers. Structure prioritised ease of maintenance at sea and controlled weight growth; reliability often trumped ultimate performance as the design criterion.

The W.B.III's design incorporated features specifically developed for naval operations. The folding wing mechanism enabled compact storage aboard carriers, a crucial requirement for maximizing the number of aircraft that could be carried. The wing-fold design balanced hinge loads against alignment accuracy, with locking pins and visual confirmations reducing human-factor errors on crowded decks. This engineering solution addressed the practical challenges of operating aircraft from limited deck space.

Material choices addressed salt‑laden environments: protective finishes, drain paths, and inspection access reduced corrosion and fluid entrapment. The naval environment presented unique challenges compared to land-based operations, with saltwater exposure, temperature variations, and limited maintenance facilities requiring robust design solutions. Beardmore's shipbuilding experience informed these material and finish choices, ensuring durability in maritime conditions.

The reinforced undercarriage represented another crucial naval adaptation. Deck landings imposed greater stresses than conventional airfield operations, requiring stronger landing gear capable of absorbing high impact loads. The W.B.III's undercarriage design incorporated lessons learned from early carrier operations, balancing strength requirements against weight constraints.

Structural design prioritized ease of maintenance at sea, where repair facilities and spare parts availability were limited. Access panels, standardized fittings, and modular construction enabled field repairs and component replacement under operational conditions. This approach reflected Beardmore's understanding of naval operational requirements, where aircraft availability depended on maintainability as much as performance.

Operations and Deck-Landing Practice: Developing Naval Aviation Doctrine

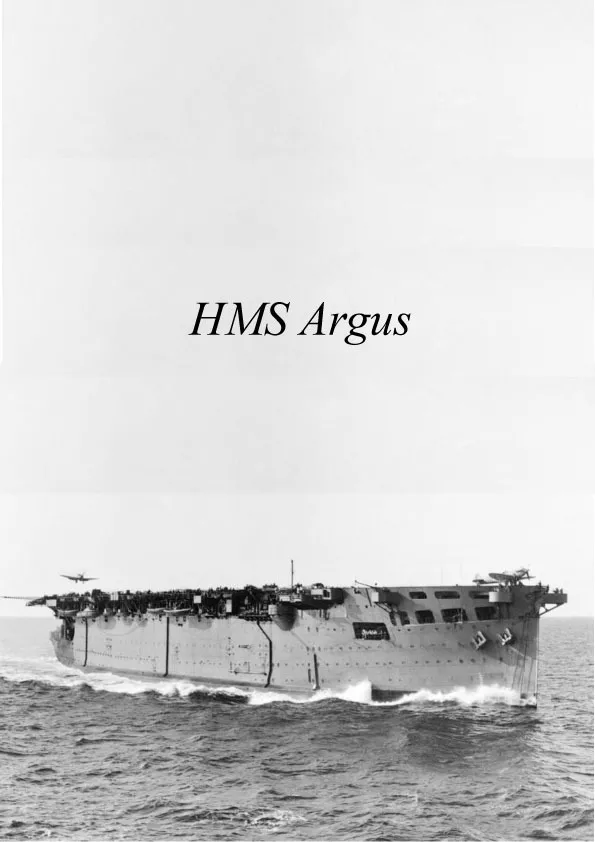

Early deck procedures evolved rapidly—barriers, wires, and signalling refined landing risks. The W.B.III stands as a developmental step: operational lessons fed back into succeeding types, while pilots developed airmanship tailored to short, moving decks and turbulent air behind the ship's island and rigging. For comprehensive coverage of HMS Argus and early carrier operations, see Aircraft Carrier - Beardmore's HMS Argus, which provides detailed accounts of the world's first true aircraft carrier and early deck-landing techniques.

HMS Argus was the world's true aircraft carrier with a flat deck, this concept being planned by the Marquis of Montrose, a Beardmore director. Built as the emigrant carrier SS Conte Rosso for the Italian Line Lloyd Sabuado at Dalmuir, Scotland, in 1914, the vessel was ultimately bought by the Admiralty in 1916. She was launched in December 1917 as HMS Argus and by 1918 was redesigned and sailed in September 1918 for Burntisland for trials with aircraft on the first carrier landings and take-offs with Sopwith aircraft including Pups.

The first aircraft carrier landings by Bell-Davis from RAF Turnhouse marked a revolutionary moment in naval aviation history. These pioneering operations established procedures and techniques that would define carrier aviation for decades. The W.B.III's development occurred during this formative period, with its design influenced by early operational experience and lessons learned from initial carrier trials.

Flight deck procedures matured through iteration: approach speeds and angles, signal flags, arrester wire spacing, and barrier heights were refined to reduce bounce and overrun. Debriefs captured hook strikes, prop clearance issues, and brake fade events, feeding back into training notes and engineering tweaks. The W.B.III's operational deployment contributed to this learning process, with each flight providing valuable data for improving naval aviation procedures.

The tests on H.M.S. Furious and the Tondern raid are covered in detail in the book, including the loss of Dunning on the hybrid carrier Furious. These operations demonstrated the challenges and possibilities of naval aviation, informing design requirements for aircraft like the W.B.III. The evolution of carrier operations from these early experiments to established procedures represents one of aviation's most significant developments.

Pilots operating the W.B.III developed specialized techniques for carrier operations. The aircraft's handling characteristics had to accommodate the unique challenges of deck landings: short approach distances, moving decks, wake turbulence, and restricted recovery areas. These operational requirements influenced design decisions, ensuring the W.B.III possessed the characteristics necessary for successful carrier operations.

Related Beardmore Naval Aircraft: The W.B. Series

The W.B.III existed within a broader family of Beardmore naval aircraft designs. The company's commitment to naval aviation produced multiple aircraft types addressing different operational requirements. Understanding the W.B.III requires examining its place within this broader design lineage and the evolution of Beardmore's naval aircraft concepts.

Beardmore designs are included including many of the projected aircraft, as documented in the book. The company's approach to naval aviation encompassed various aircraft types, from fighters to reconnaissance aircraft, each addressing specific operational needs. The W.B.III represented one aspect of this comprehensive naval aviation programme, demonstrating Beardmore's systematic approach to addressing Royal Naval Air Service requirements.

The evolution of Sopwith aircraft produced by Beardmore, including Camel operations off cruisers and the carriers Argus and Furious, demonstrates the company's role in naval aviation manufacturing. The Beardmore-built Sopwith Camel N6812, preserved in the Imperial War Museum, represents the quality and reliability of Beardmore-built aircraft in naval operations. For comprehensive coverage of British naval aircraft during this period, see British Aircraft of the Great War, which includes detailed information on shipboard aircraft and naval aviation operations.

Other aircraft types produced by Beardmore during the war included the Wight Seaplane, the Nieuport XII, the pre-war D.F.W.s, the B.E.2C, and culminating in the production of the Handley Page V1500. Each type had its own unique production challenges and operational requirements, demonstrating Beardmore's versatility in aircraft manufacturing and their commitment to meeting diverse naval aviation needs.

Industrial Ecosystem and the Clyde: Scottish Manufacturing Excellence

The Clyde's steel, machine, and shipbuilding capacity enabled short supply lines for fixtures, forgings, and repair. Collaboration between yards and airframes accelerated iteration, with naval requirements shaping design priorities distinct from land-based fighters. The book covers the history of aircraft production in Glasgow and the West of Scotland, set up by the Weir brothers, providing insights into the industrial context that enabled Beardmore's aviation achievements.

Shipyard metrology and lifting gear complemented airframe assembly: jigs, rotators, and precision boring supported repeatable assemblies. Local test facilities, including catapult trials and static load rigs, shortened development cycles and aligned manufacturing with operational reality. This industrial infrastructure enabled Beardmore to undertake complex aircraft projects that would have been challenging for less well-equipped manufacturers.

Beardmore's production programmes for aero-engines and aeroplanes in the First World War were undertaken for the British Ministry of Munitions, supplying the Royal Flying Corps, Royal Naval Air Service, and the infant Royal Air Force (RAF). The company's production lines manufactured a diverse range of aircraft types, with naval aircraft like the W.B.III representing one component of this comprehensive manufacturing effort.

The company's production figures, documented with unprecedented accuracy in the book, reveal the scale of Beardmore's contribution to British naval aviation. Engine and airframe totals and production figures for the First World War are rarely published, making this documentation particularly valuable for historians and researchers. The comprehensive statistical records provide insights into production rates, quality control, and manufacturing efficiency during a period of intense demand.

For those interested in the broader context of Scottish aviation manufacturing during this period, Clydeside Aviation Volume One: The Great War provides comprehensive coverage of aircraft production across the Clyde region, including Beardmore's role in the broader Scottish aviation industry. The book documents the diverse range of aircraft types built on Clydeside, demonstrating the region's industrial capability and aviation manufacturing expertise.

Technical Specifications and Design Details

The W.B.III incorporated technical features specifically developed for naval operations. The aircraft's structure balanced performance requirements with the constraints imposed by carrier operations, including weight limitations, storage requirements, and maintenance considerations. Understanding these technical specifications provides insights into the engineering challenges faced in developing naval fighters during the First World War.

The folding wing mechanism represented one of the W.B.III's most significant technical innovations. This feature enabled compact storage aboard carriers, maximizing the number of aircraft that could be accommodated. The mechanism's design required careful engineering to ensure reliability while maintaining structural integrity. The wing-fold system incorporated locking mechanisms and visual indicators to prevent accidental deployment during flight operations.

Corrosion protection systems addressed the unique challenges of maritime operations. Saltwater exposure, high humidity, and temperature variations required protective finishes and drainage systems that prevented corrosion and fluid entrapment. These systems reflected Beardmore's shipbuilding expertise, applying proven maritime protection techniques to aircraft construction.

The reinforced undercarriage design accommodated the high-impact loads associated with deck landings. Conventional airfield landings imposed different stresses than carrier operations, requiring stronger landing gear capable of absorbing greater forces. The W.B.III's undercarriage incorporated design features developed specifically for naval operations, demonstrating attention to operational requirements.

Powerplant integration addressed naval aviation requirements, with engine selection and installation considering factors including reliability, maintenance accessibility, and operational performance. The W.B.III's engine installation reflected understanding of carrier operational constraints, where maintenance facilities and spare parts availability were limited compared to land-based operations.

Operational Deployment and Combat Service

The W.B.III's operational deployment occurred during a crucial period in naval aviation development. As carrier operations evolved from experimental trials to established procedures, aircraft like the W.B.III provided the platforms necessary for developing naval aviation doctrine. The aircraft's service history reflects the challenges and achievements of early carrier operations.

The history of the deployment of the Sopwith Pup and the Sopwith Camel with the R.N.A.S., including combat details and early aircraft carrier deployment, provides context for understanding the W.B.III's operational environment. These operations demonstrated the potential of naval aviation while revealing the challenges that required specialized aircraft designs like the W.B.III.

Carrier operations imposed unique operational requirements compared to land-based aviation. Limited deck space, moving platforms, and maritime conditions required specialized techniques and aircraft characteristics. The W.B.III's design incorporated features addressing these requirements, enabling successful carrier operations while contributing to the development of naval aviation procedures.

Operational experience with the W.B.III informed subsequent naval aircraft designs, with lessons learned contributing to improved designs and operational procedures. The aircraft's deployment provided valuable data on carrier operations, aircraft handling characteristics, and maintenance requirements in maritime environments. This operational feedback loop accelerated naval aviation development.

The W.B.III's service demonstrated the effectiveness of Scottish industrial capability in meeting naval aviation requirements. Beardmore's ability to produce aircraft meeting operational needs while incorporating specialized naval features illustrated the company's engineering capability and understanding of naval requirements. This achievement contributed to Britain's naval aviation capability during the First World War.

Comparison with Contemporary Naval Aircraft

The W.B.III existed within a competitive environment of naval aircraft development during the First World War. Comparison with contemporary designs provides insights into design choices, operational effectiveness, and the evolution of naval aviation technology. Understanding these comparisons illuminates the W.B.III's place within naval aviation development.

The Sopwith Pup and Sopwith Camel represented successful naval fighter designs, with Beardmore producing Camels under licence. The evolution of these Sopwith aircraft included Camel operations off cruisers and the carriers Argus and Furious, demonstrating the diversity of naval aviation operations and the range of aircraft types required. The W.B.III existed alongside these designs, each addressing different aspects of naval aviation requirements.

Other naval aircraft types produced during this period included the Wight Seaplane, the Nieuport XII, and various seaplane designs. Each type addressed specific operational requirements, with designs optimized for different missions and operational environments. The W.B.III's specialized features represented one approach to meeting naval aviation needs.

The comparison between land-based and naval aircraft designs reveals the unique challenges of carrier operations. Naval aircraft required features including folding wings, reinforced structures, and specialized equipment that were unnecessary for land-based operations. These requirements influenced design choices, sometimes compromising performance for operational capability.

International naval aircraft development during this period included designs from various nations, each addressing carrier operations differently. The W.B.III's design reflected British naval aviation requirements and operational experience, contributing to the development of procedures and techniques that would influence subsequent naval aircraft designs.

Manufacturing Processes and Quality Control

Beardmore's manufacturing processes incorporated quality control systems, precision jigs, and systematic production methods that ensured consistent output. The company's ability to rapidly scale production while maintaining quality standards demonstrated their industrial sophistication. The detailed documentation of production processes, preserved in company archives, provides valuable insights into early aviation manufacturing techniques.

The book has accurate production figures deeply researched from Beardmore archive records in Scotland and London with contract numbers never before published. These records reveal the true scale of Beardmore's contribution to British naval aviation during the First World War. The comprehensive statistical documentation provides insights into production rates, quality control, and manufacturing efficiency.

Precision jigs and manufacturing fixtures enabled repeatable production of aircraft components, ensuring consistency across production batches. These manufacturing tools reflected Beardmore's engineering expertise and attention to production quality. The company's shipbuilding experience informed their approach to aircraft manufacturing, applying proven industrial techniques to aviation production.

Quality control systems ensured that aircraft met specification requirements and operational standards. Inspection procedures, documentation systems, and testing protocols maintained production quality while enabling rapid production rates. These systems reflected Beardmore's commitment to manufacturing excellence and their understanding of aviation production requirements.

The company's manufacturing capability enabled rapid response to operational requirements, with production adapting to changing needs and priorities. This flexibility demonstrated Beardmore's industrial capability and their commitment to supporting naval aviation operations. The W.B.III's production reflected these manufacturing capabilities, enabling timely delivery of aircraft meeting operational requirements.

Testing, Trials, and Development

The W.B.III's development involved extensive testing and trials to validate design features and ensure operational suitability. These tests addressed various aspects of naval operations, including deck handling, folding mechanism reliability, structural integrity under operational loads, and performance characteristics. The testing programme reflected Beardmore's commitment to ensuring aircraft met operational requirements.

Carrier trials involved testing aircraft operations aboard actual carriers, providing realistic operational conditions and opportunities to validate design features. These trials revealed practical challenges and requirements that informed design refinements and operational procedures. The W.B.III's participation in these trials contributed to naval aviation development and operational capability.

Structural testing validated design loads and safety margins, ensuring aircraft could withstand operational stresses including deck landings, catapult launches, and carrier operations. These tests informed design refinements and validated engineering calculations, ensuring structural integrity under operational conditions.

Performance testing evaluated aircraft characteristics including speed, climb rate, maneuverability, and operational range. These tests provided data on aircraft capabilities and limitations, informing operational employment and tactical considerations. The W.B.III's performance characteristics reflected design choices balancing various operational requirements.

Development testing addressed specific naval aviation features including folding mechanisms, deck handling equipment, and specialized systems. These tests validated engineering solutions and identified areas requiring refinement. The iterative development process incorporated test results into design improvements, ensuring aircraft met operational requirements.

Maintenance, Support, and Operational Logistics

Naval aircraft operations required maintenance and support systems adapted to carrier environments. Limited space, restricted facilities, and operational constraints imposed unique maintenance challenges. The W.B.III's design incorporated features addressing these requirements, enabling effective maintenance under operational conditions.

Access panels and modular construction enabled field repairs and component replacement without extensive facilities. These design features reflected understanding of carrier operational constraints, where maintenance capabilities were limited compared to land-based operations. The W.B.III's maintainability contributed to operational availability and effectiveness.

Spare parts provisioning and supply chain management addressed carrier operational requirements, ensuring availability of components necessary for maintaining aircraft operational capability. These logistics considerations reflected Beardmore's understanding of naval aviation operational needs and their commitment to supporting operational effectiveness.

Training and documentation enabled maintenance personnel to effectively support aircraft operations. Technical manuals, maintenance procedures, and training programmes ensured proper aircraft care and repair. These support systems reflected Beardmore's commitment to operational effectiveness and their understanding of maintenance requirements.

Operational experience with the W.B.III informed maintenance procedures and support systems, with lessons learned contributing to improved effectiveness. The aircraft's deployment provided opportunities to refine maintenance approaches and identify areas requiring improvement. This operational feedback accelerated naval aviation support capability development.

Legacy and Historical Assessment

The W.B.III's significance is cumulative: it contributed to the carrier-fighter lineage by hardening structures, practices, and culture. Later naval aircraft absorbed its lessons, while Clyde's industrial breadth sustained aviation projects beyond the war. The pathway from W.B.III to later deck fighters traces continuity in folding schemes, arresting gear interfaces, and pilot training syllabi. Scotland's contribution lay not only in airframes but in the enabling infrastructure and doctrine.

MacKay's Beardmore Aviation book, with 238 pages profusely illustrated in 61,000 words, has proved an excellent reference work for students, historians and general readers alike. The book has been printed multiple times since 2012 and is now in continuous print due to demand, demonstrating its value as a historical resource. The information contained within is not available in any other publication, making it essential reading for anyone interested in Scottish naval aviation history.

Beardmore's aviation legacy extends beyond their direct manufacturing achievements. The company's development of manufacturing processes, quality control systems, and production techniques influenced subsequent naval aviation manufacturing in Scotland and beyond. The skills and knowledge developed during their aviation years contributed to Scotland's broader industrial capability and positioned the region as a centre of naval aviation excellence.

The W.B.III's development demonstrated the effectiveness of applying shipyard engineering expertise to aviation manufacturing. Beardmore's ability to transition from shipbuilding to aircraft production while maintaining engineering standards illustrated the adaptability of Scottish industry and its capability to address emerging technological requirements. This achievement contributed to Britain's naval aviation capability during the First World War.

Modern naval aviation reflects lessons learned from early carrier operations and aircraft designs like the W.B.III. Folding wings, reinforced structures, and specialized deck handling equipment remain essential features of naval aircraft. The fundamental challenges of carrier operations identified during the W.B.III's development continue to influence naval aircraft design and operational procedures.

Academic Recognition and Research Value

The book has received five-star reviews and is based on extensive original research. It is not a compendium of Wikipedia articles or a compilation of search answers from web sites - this is an original work based on primary archival sources. The research methodology and source documentation make this an essential reference for academic researchers studying British naval aviation history, Scottish industrial development, and First World War manufacturing.

Each section is supported by tables of statistics and the book has a comprehensive bibliography and appendix. These scholarly features ensure that the work meets academic standards while remaining accessible to general readers. The rigorous documentation of sources and comprehensive statistical analysis provide a solid foundation for further research and academic study.

The book's value to researchers extends beyond aviation history. It provides insights into industrial organization, manufacturing processes, labour relations, and technological innovation during a crucial period in British history. The detailed documentation of production figures, contract numbers, and operational histories creates a comprehensive resource for understanding early twentieth-century industrial development.

The W.B.III's documentation contributes to understanding naval aviation development during the First World War. The comprehensive coverage of design, production, and operational aspects provides valuable insights into early carrier aviation and the evolution of naval aircraft technology. This documentation preserves crucial historical information for future researchers and historians.

Conclusion: A Scottish Contribution to Naval Aviation

The Beardmore W.B.III represents a significant contribution to British naval aviation during the First World War. From shipyard ingenuity to deck-landing realities, Scottish engineering expertise successfully addressed the unique challenges of carrier operations. The aircraft's development, production, and operational deployment demonstrated Beardmore's capability to undertake complex aviation projects while maintaining engineering standards and meeting operational requirements.

MacKay's authoritative work ensures that this remarkable story is preserved for future generations. The book's thorough research, detailed illustrations, and careful documentation create an authoritative resource that does justice to Beardmore's achievements and contributions to naval aviation progress. This scholarly work ensures that Scotland's naval aviation contribution receives the recognition it deserves.

The W.B.III's legacy extends beyond individual achievements to influence broader naval aviation development. The aircraft's design features, operational experience, and manufacturing techniques contributed to subsequent naval aircraft development and operational procedures. The fundamental challenges of carrier operations identified during the W.B.III's development continue to influence naval aviation, demonstrating the lasting significance of these early achievements.

Further Reading and Related Works

For comprehensive coverage of Beardmore's naval aviation history and related topics, explore these authoritative works by Charles E. MacKay:

- Beardmore Aviation: The Story of a Scottish Industrial Giant's Aviation Activities — The definitive 238-page work with 61,000 words, profusely illustrated with many original images and accurate production figures from Beardmore archive records

- Aircraft Carrier - Beardmore's HMS Argus — Complete history of the world's first true aircraft carrier, from conception to scrapping, including detailed coverage of early deck-landing operations

- Clydeside Aviation Volume One: The Great War — Comprehensive coverage of aircraft production across the Clyde region, including Beardmore's naval aircraft and the broader Scottish aviation industry

- British Aircraft of the Great War — Detailed information on shipboard aircraft and naval aviation operations, including Beardmore-built aircraft

- Captain Eric "Winkle" Brown: Test Pilot Biography — Includes details of Brown's service as an instructor on HMS Argus, built by Beardmore, providing insights into carrier operations

Related Articles

- HMS Argus: The World's First Aircraft Carrier — Detailed coverage of the carrier that pioneered deck-landing operations

- Beardmore Aviation: Scottish Industrial Giant — Comprehensive coverage of Beardmore's aviation achievements

- Clydeside Aviation Revolution — How Glasgow's shipyards transformed into aviation powerhouses

- British Aircraft Great War: RFC & RNAS Development — The broader context of British naval aviation during the First World War

References

- Royal Air Force Museum — Aircraft Collection — Royal Air Force Museum

- Imperial War Museums — Aviation History Articles — Imperial War Museums

- FlightGlobal Archive — FlightGlobal